Provision of consultation services in mold manufacturing & design area consists of:

- Project Management

- Design For Manufacturabilty (DFM)

- Mold Flow Anaiysis

- 2D/3D Mold Design

- Mold Testing Report

- Mechanical Function Check and Debugging

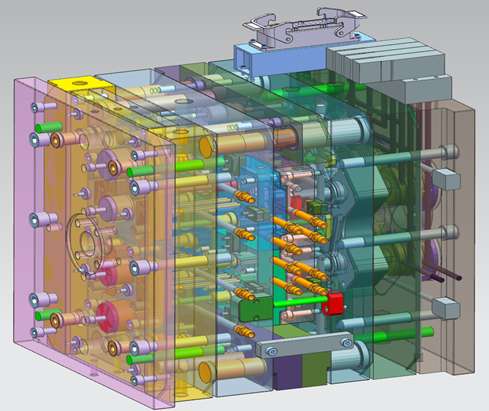

Hi-Tech manufacture export grade molds with size ranges from 6" x 6" to 40" x 60". In the Spring of 2011, Hi-Tech valuable sophisticated "Flexible Manufacturing Cell" (FMC) is being well utilized. The FMC consists of robotic handling system, high speed CNC machining centers, EDM and CMM.

Equipped with 59 sets of horizontal, vertical and co-injection machines, (40 to max. 450 ton) along with peripherals such as robotic automation, chillers, water pressure gauge, mold temperature regulators and dehumidifiers to optimize and presume maximum molding conditions.

Provision of Molding testing by molding the samples in both the best adjusted parameters and extreme conditions.

Molding small and large quantity samples for engineering evaluation, pilot run or pre-production purposes.

4 assembly lines are established as value-added service to customers' needs.

In order to achieve high effective production and cost cut on labor, Hi-Tech setup automation department to develop and design tailor made assembly machines to fulfill production demands.